raSmith provides planning, engineering, and construction oversight services for sanitary sewer rehabilitation projects to Wisconsin local governments. These essential services support local governments in enhancing their infrastructure. raSmith’s expertise has benefited numerous municipalities including the City of West Allis, City of Wauwatosa, Village of Menomonee Falls, Village of Germantown, City of New Berlin, Village of Greendale, Village of Bayside, and City of Greenfield, among others.

Within the overall umbrella of sanitary sewer evaluation and rehabilitation is the essential management of private property infiltration and inflow (PPII) via home inspections. Infiltration refers to groundwater seeping into the sanitary sewer system through defects in sanitary sewer pipes. Conversely, inflow is the entry of clear water (distinct from sewage wastewater) into the system through direct connections such as downspouts from roof drains, foundation drain connections, and cross connections with storm drains.

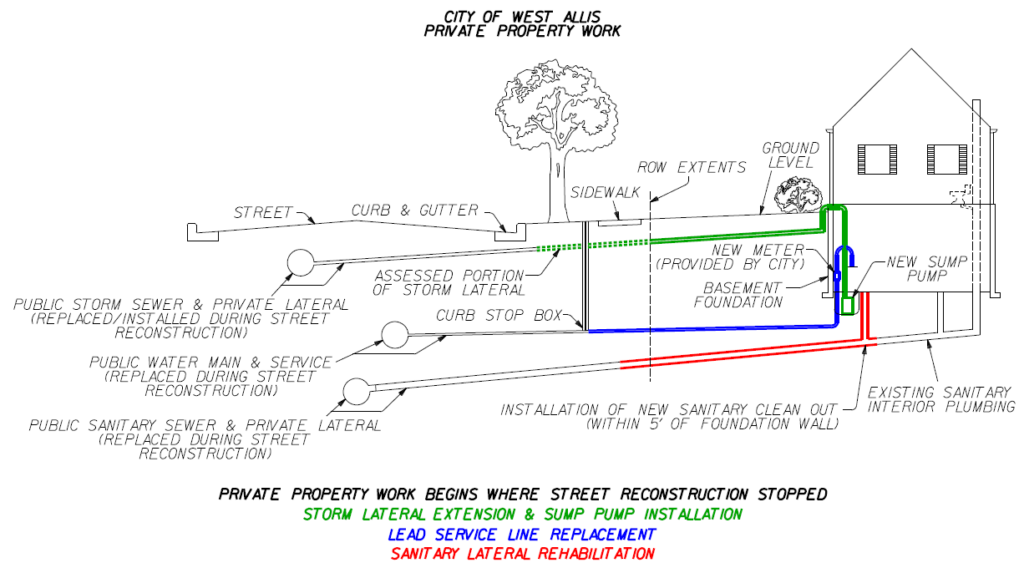

Homeowners are responsible for certain property improvements and must agree to share a portion of the associated costs. These improvements can encompass a range of services including the replacement of private lead service water lines, installation of sump pumps, storm laterals, and rehabilitation of sanitary sewer laterals. The latter may involve advanced techniques such as pipe bursting or cured-in-place pipe (CIPP) lining.

Homeowners are responsible for certain property improvements and must agree to share a portion of the associated costs. These improvements can encompass a range of services including the replacement of private lead service water lines, installation of sump pumps, storm laterals, and rehabilitation of sanitary sewer laterals. The latter may involve advanced techniques such as pipe bursting or cured-in-place pipe (CIPP) lining.

The following is a case study from a recent PPII project in West Allis, located in Milwaukee County, Wisconsin. The narrative showcases the collaborative efforts of this rehabilitation project, insights into the strategies employed, and the outcomes and impacts on the local community. This project serves as a strong example of effective public-private partnerships in urban development.

2024 Case Study: 77th Street, West Allis

raSmith’s marketing team recently captured photos and video of a project along 77th Street in West Allis. For this residence, approximately 30 feet of private sanitary sewer lateral and water service were replaced from the right-of-way extents to the home. This home is among the approximately 70 residences in West Allis that have benefited from raSmith’s home inspection services in 2024. raSmith conducted inspection services for 80 homes in 2022 and 75 homes in 2021. In 2021 and 2022, the program included foundation drain disconnection, sump pump installation, and storm lateral connections as part of the program.

Essential Steps in Rehabilitating Infrastructure for West Allis’ PPII Project

1) Prior to street reconstruction. West Allis previously rebuilt the streets in the project area. All of the utilities within the right-of-way including sewer laterals and water services were replaced to the right-of-way. This project will replace them from the right-of-way to the inside of the house.

2) Homeowner interest and sign up. West Allis solicited homeowners within the project area to sign up for the sewer lateral replacement and lead service replacement.

3) Initial coordination. Prior to construction, the contractor and raSmith inspector conducted a pre-construction visit. The project was explained to the owner, and the basement’s condition and any work the homeowner needed to do prior to the first day of construction was documented by raSmith’s construction oversight professionals.

4) Excavation and exposure. The sanitary sewer lateral and water service were exposed by excavating at the right-of-way. It was necessary to remove sidewalk sections to perform the construction work.

5) Basement preparation. An electric jack hammer was used to break up the basement floor around the sewer cleanout, which was then hand-dug and removed.

6) Pipe installation. High-density polyethylene pipe (HDPE) was brought into the basement in sections of HDPE, ranging in length from 12 to 20 feet (this amount varies depending on basement layout). The pipes were placed in a McElroy fusion machine. The ends were heated for about two minutes by a 400- to 450-degree heating plate and then fused together by pushing and holding the sections together for about five minutes. The result was a jointless, leak-free pipe. The new pipeline was then pulled into place with the use of a HammerHead pipe puller located in the excavation area at the right-of-way.

7) Sewer connection. A new sewer cleanout was installed, and the pipe was reconnected to the sewer under the basement floor. The pipe was pressure-tested before final connection.

7) Sewer connection. A new sewer cleanout was installed, and the pipe was reconnected to the sewer under the basement floor. The pipe was pressure-tested before final connection.

8) Water service replacement. The lead water service line was replaced by excavating at the curb stop in conjunction with exposing the sewer lateral. A new one-inch copper water service was pulled into place during the pipe bursting of the sewer lateral.

9) Final connections. The new water service was connected to the meter. The plumber connected the meter to the existing copper piping near the ceiling above the water heater.

9) Final connections. The new water service was connected to the meter. The plumber connected the meter to the existing copper piping near the ceiling above the water heater.

10) Safety precautions. The contractor took precautions to protect the existing gas and electrical lines for the street lighting. An electrician reinstalled the ground wire. A trench box was used in the excavation to protect workers.

11) Site restoration. The sidewalk was backfilled with chips and recycled materials, and the basement floor was replaced around the new cleanout. The sidewalk was replaced within a week, and grass was planted in the disturbed areas.

12) Quality assurance. Crew members performing the pipe fusing are required to be trained and certified. raSmith has multiple on-site construction monitoring professionals who are trained and certified in HDPE pipe fusion. CCTV (closed-circuit television) was used to inspect the new sewer lateral to ensure flow was unrestricted.

raSmith’s Role in the West Allis Private Property Inflow and Infiltration (I&I) Project

raSmith’s Role in the West Allis Private Property Inflow and Infiltration (I&I) Project

raSmith ensured that MJ Construction adhered to the project’s plans and specifications, providing construction oversight. This oversight included compliance with all relevant state and local agency requirements such as those from the City of West Allis, Milwaukee Metropolitan Sewerage District (MMSD), and Wisconsin Department of Natural Resources (WDNR).

A significant challenge successfully handled by raSmith was the continuous coordination required among the owner, contractors, and homeowners. The raSmith team prioritized keeping residents well-informed and involved throughout the construction occurring on their properties, which was crucial for the project’s success. Additionally, raSmith’s responsibilities extended to a comprehensive coordination of building inspections, providing engineering design services to address emerging challenges during construction, ensuring quality assurance and control, compiling daily inspection reports, and determining installed construction quantities.

The team at raSmith has attended MMSD’s annual PPII workshop, equipping them with essential knowledge for collaboration with local governments, contractors, and homeowners. This training is pivotal for adhering to MMSD’s standards and implementing industry best practices. To explore training opportunities, please visit MMSD’s website.

Funding for the City of West Allis PPII Project and Other Available Resources

The City of West Allis 2024 I&I initiative received substantial funding from the MMSD’s PPII program. Additionally, the WDNR has contributed to project funding for the lead service replacement in previous years. Homeowners who participated in the 2024 program were each assessed $2,000 for the lead service replacement.

For sanitary sewer rehabilitation, lead line replacement, and other related projects, a range of funding sources are available. To explore resources, you may request access to raSmith’s online grants directory at www.rasmith.com/grant. For further assistance, please reach out to Karen Wiesneski, grants specialist, via email at karen.wiesneski@rasmith.com or (262) 317-3292.

Additional Information

raSmith staff have published a couple additional blogs relevant to sanitary sewer system rehabilitation:

1) “Revitalizing Communities: The Essential Role of Sanitary Sewer Rehabilitation Programs.” This piece discusses the critical importance of rehabilitating sanitary sewer systems to prevent public health risks, environmental damage, and economic losses caused by deterioration due to multiple factors over time.

2) “Revolutionizing Sewer Rehabilitation: The Power of Flow Monitoring Innovations.” This blog post examines the use of state-of-the-art sensor technology to pinpoint locations in sewer systems that lead to I&I challenges.

How raSmith Can Help

For more information about raSmith’s sanitary sewer and water service line rehabilitation services, please contact Chris Stamborski, P.E, at chris.stamborski@rasmith.com, (262) 317-3337, or Ben High, P.E., at ben.high@rasmith.com, (262) 317-3273.