Project Overview

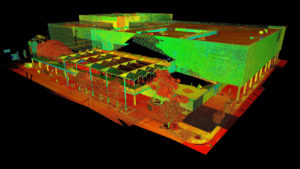

North of Pittsburgh, ATI’s Brackenridge plant went through a $1.2 billion modernization redevelopment that makes it the most advanced hot rolling and processing facility in the world for specialty stainless steel, titanium, alloys and more.

With a need for accurate survey control to be set, ATI called upon raSmith to establish and maintain a high accuracy control network. The multi-year, 12-phase project construction required raSmith’s survey teams to stake more than 6,000 “H” pile locations, checking plumbness for each and creating as-builts for each. Due to the size of the project, raSmith was retained to verify the construction layout performed by four independent sub-consultants, and verify installation of more than 1,500 column anchor bolt as-builts, 25,000 bolt-can locations and 21,000 linear feet of crane-rail installation.

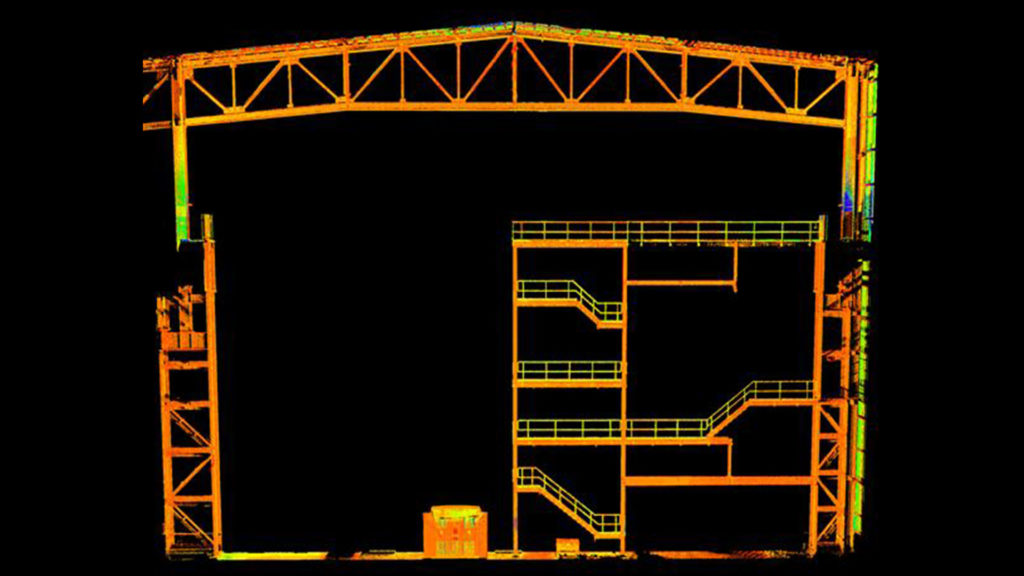

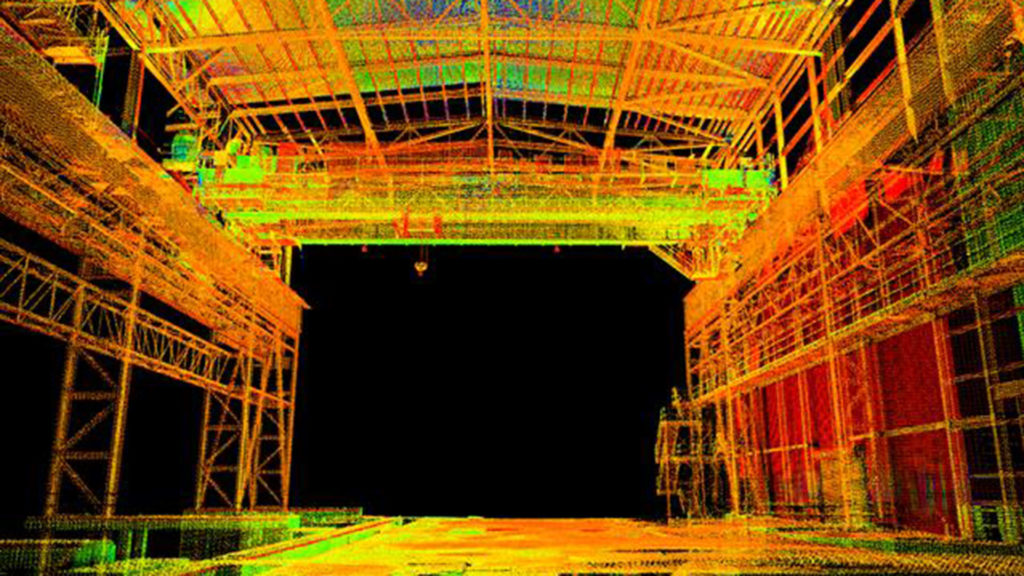

raSmith also provided LiDAR (3D laser scanning) services for the 650,000-square-foot newly constructed industrial building and crane rail system within the industrial plant. More than 12,000 linear feet of rail system was scanned to provide asbuilt reports for 15 different items at each of the nearly 200 column and mid-span locations. These reports were used to determine if the newly constructed rail system was built within the stringent tolerances.

raSmith also utilized 3D laser scanners to capture highly accurate as-built locations of the newly constructed structural steel members. The compiled and dense levels of registered data were used to create cross sections of the structural members to identify placement of the members as well as their plumbness, through a series of more than 20 dimensions at each column line and column mid-span location.